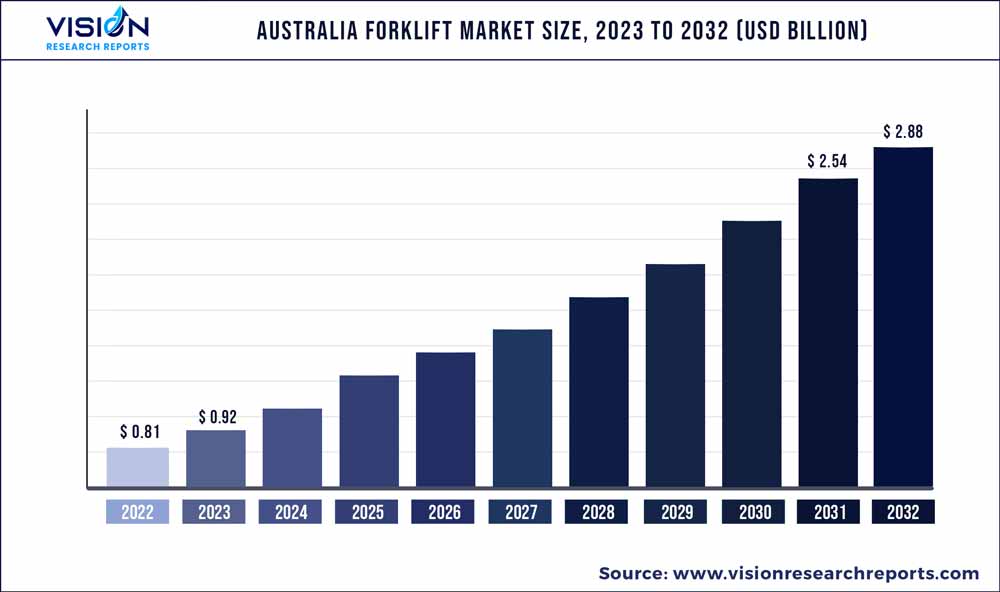

The Australia forklift market size was estimated at around USD 0.81 billion in 2022 and it is projected to hit around USD 2.88 billion by 2032, growing at a CAGR of 13.54% from 2023 to 2032.

Key Pointers

Report Scope of the Australia Forklift Market

| Report Coverage | Details |

| Market Size in 2022 | USD 0.81 billion |

| Revenue Forecast by 2032 | USD 2.88 billion |

| Growth rate from 2023 to 2032 | CAGR of 13.54% |

| Base Year | 2022 |

| Forecast Period | 2023 to 2032 |

| Market Analysis (Terms Used) | Value (US$ Million/Billion) or (Volume/Units) |

| Companies Covered | CLARK; Crown Equipment Corporation; Doosan Corporation; Hangcha; Hyster-Yale Materials Handling, Inc.; Jungheinrich AG; Komatsu Ltd.; Toyota Material Handling |

The rising demand for port-related operations drives the market’s growth. The country's robust economic growth and extensive global trade connections have propelled international commerce. Australia holds a prominent position as a major exporter of minerals, agricultural products, and liquefied natural gas commodities. Furthermore, the import of consumer goods, machinery, and industrial equipment has experienced substantial growth.

Hence, ports in Australia observe a notable increase in container material, necessitating efficient material handling solutions such as forklifts. With their versatility, maneuverability, and capability to handle heavy loads, forklifts have become essential equipment for port terminals, warehouses, and distribution centers.

In recent years, there has been a significant shift towards using electric forklifts in Australia due to a high emphasis on sustainability and reducing carbon emissions. growing government concern for the environment and the need to minimize harmful pollutants is resulting in a shift toward the adoption of electric material handling solutions.

Electric forklifts achieve this goal by producing no tailpipe emissions and enhancing indoor air quality which is increasing their preference among warehouse owners and product manufacturers. As environmental consciousness grows and regulations become more stringent, businesses increasingly move away from traditional ICE forklifts and embrace electric alternatives. The prioritization of sustainability and the need to optimize operations have made electric forklifts the preferred choice.

Fluctuating raw materials prices have emerged as a significant restraint on the growth of the Australia forklift market. The instability and unpredictability of costs for essential components such as steel, rubber, and fuel pose challenges for manufacturers and suppliers in maintaining consistent pricing and profitability. These price fluctuations disrupt production planning, inventory management, and the ability to offer competitive prices to customers. Hence, businesses considering investing in forklifts may hesitate due to the uncertain cost implications associated with these vital materials. This uncertainty affects the manufacturing and logistics sectors that rely on efficient material handling solutions.

The utilization of automation and robotics has brought about a transformative impact on the handling, transportation, and management of materials within industrial settings. Smart forklift machines are equipped with advanced sensors, computer vision capabilities, and artificial intelligence algorithms, enabling them to navigate intricate environments, execute tasks efficiently, and adapt to dynamic conditions.

By integrating sensor and camera technology into forklifts, businesses are experiencing significant productivity, safety, and operational efficiency improvements while minimizing the risks associated with human errors, accidents, and downtime. As a result, Australian companies are increasingly embracing autonomous forklifts to optimize their logistics and supply chain operations, thereby driving the growth of the Australia forklift market in the country.

The rising demand for efficient material handling solutions has prompted forklift manufacturers and suppliers to prioritize the development of cutting-edge technologies. These advancements aim to enhance the industry's productivity, safety, and sustainability. One notable area of progress is the integration of automation and artificial intelligence (AI) capabilities into forklifts. This includes the implementation of autonomous navigation systems and object detection mechanisms, resulting in improved accuracy and reduced human error.

Such innovations contribute to the overall efficiency of material handling operations. As a result, logistics, warehousing, and manufacturing industries can address their growing needs while aligning with sustainability goals. These technological advancements position Australia at the forefront of innovative forklift solutions and surge new business opportunities. By staying at the forefront of these developments, businesses can tap into the growing demand for advanced forklift technologies and cater to the evolving needs of various industries.

Tonnage Capacity Insights

The below 5 tons segment accounted for the largest market share of over 51% in 2022 and is anticipated to register the highest CAGR over the forecast period. The flexibility of these machines enables efficient and timely movement and transportation of goods. Moreover, the rising focus on workplace productivity and operational efficiency has led businesses to invest in the below 5-ton forklifts.

These forklifts offer improved maneuverability, compact size, and increased load capacities, enabling operators to navigate tight spaces and handle diverse loads easily. With continuous advancements in forklift technology and the increasing demand for agile material handling equipment, the demand for Below 5 Ton forklifts remains robust in Australia. They continue to play a vital role in enhancing overall productivity and safety in the industrial sector.

The 6-30 tons segment is expected to register significant growth over the forecast period. The rise of e-commerce has sparked a surge in demand for efficient material handling equipment, particularly larger capacity forklifts, to cater to the growing warehousing and logistics requirements.

Furthermore, the agricultural sector's push for mechanization to boost productivity and streamline operations has opened up opportunities for these forklifts to handle bulk materials such as fertilizers and produce. With a strong focus on sustainability and emission reduction, the shift towards electric forklifts emerges as a promising avenue for growth, given the increasing emphasis on environmental regulations and incentives. Hence, the Australian market exhibits substantial potential for expanding and adopting the segment across various industries.

Class Insights

The class 4/5 segment accounted for the largest market share of over 62% in 2022. The primary factors propelling the development of these forklifts are cutting-edge technology and design elements that amplify efficiency. These include electric or ICE, ergonomic controls, and enhanced lifting capabilities.

Moreover, the implementation of regulatory mandates and occupational health and safety considerations significantly contribute to the widespread use of these forklifts. Compliance with specific standards is essential for legal operations and safeguarding workers. Environmental consciousness and the increasing focus on sustainability have fuelled the adoption of electric-powered Class 4/5 forklifts. These models minimize emissions and encourage eco-friendly practices.

The Class 3 segment is expected to register the highest CAGR over the forecast period. Electric motor hand trucks, called Class 3 forklifts, are well-suited for indoor operations due to their enhanced maneuverability, improved energy efficiency, and reduced emissions. The demand for electric forklifts is further fuelled by the increasing emphasis on sustainability and government initiatives that promote environmentally friendly practices. Class 3 forklifts can navigate narrow spaces, handle lighter loads, and contribute to a greener environment. As a result, they are poised to capture a significant market share and thrive in Australia's evolving logistics landscape.

Power Source Insights

The internal combustion engines (ICE) forklift segment accounted for the largest market share of over 61% in 2022. In Australia, traditional fossil fuels such as gasoline or diesel are the primary power sources for ICE forklifts. These forklifts rely on internal combustion engines to convert the chemical energy stored in these fuels into mechanical power.

This power is used to drive the vehicle's wheels or hydraulic systems. The engines follow a combustion cycle, igniting fuel in a combustion chamber and producing expanding gases. These gases move pistons and generate rotational motion. The motion is then transmitted through the transmission system to the wheels or hydraulic pumps, allowing the forklift to efficiently perform lifting, carrying, and maneuvering tasks in various industrial and warehouse environments throughout the country.

The electric forklift segment is anticipated to register the highest CAGR over the forecast period. The nation's dedication to sustainability and the reduction of carbon emissions is in harmony with the benefits offered by electric forklifts, which emit no tailpipe pollutants. Moreover, the escalating expenses associated with conventional fuel options, coupled with the growing accessibility of renewable energy, enhance the economic viability of electric forklifts. Furthermore, the expanding e-commerce industry and the requirement for efficient, eco-friendly logistics solutions generate a robust demand for electric forklifts within warehouses and distribution centers.

Product Type Insights

The counterbalance segment accounted for the largest market share of nearly 67% in 2022 and is anticipated to register the highest CAGR over the forecast period. The demand for counterbalance forklifts in various industries, such as warehousing, manufacturing, and construction, stems from the imperative to optimize productivity and streamline logistics operations.

These versatile machines, designed with a weight-bearing rear structure to maintain balance while handling heavy loads, facilitate efficient lifting, transporting, and stacking of goods, resulting in improved operational efficiency. The increasing focus on sustainability and reducing carbon emissions has propelled the adoption of electric counterbalance forklifts. These eco-friendly alternatives contribute to a greener approach to material handling. The convergence of these factors, coupled with the demand for effective and safe material handling practices, drives the segment’s growth.

The warehouse segment is expected to register considerable growth over the forecast period. The e-commerce industry is experiencing significant growth, resulting in a surge in demand for efficient warehousing and logistics operations. As many businesses embrace online retail models, warehouses need advanced forklift technologies to handle larger inventories and optimize order fulfillment processes effectively.

Furthermore, expanding manufacturing and construction sectors adds to the requirement for warehouses equipped with forklifts to manage material handling tasks. With a burgeoning economy and a rapidly evolving business landscape, investing in modernized warehouses with cutting-edge forklift solutions enables companies to capitalize on the thriving market.

Australia Forklift Market Segmentations:

By Tonnage Capacity

By Class

By Power Source

By Product Type

Chapter 1. Introduction

1.1. Research Objective

1.2. Scope of the Study

1.3. Definition

Chapter 2. Research Methodology

2.1. Research Approach

2.2. Data Sources

2.3. Assumptions & Limitations

Chapter 3. Executive Summary

3.1. Market Snapshot

Chapter 4. Market Variables and Scope

4.1. Introduction

4.2. Market Classification and Scope

4.3. Industry Value Chain Analysis

4.3.1. Raw Material Procurement Analysis

4.3.2. Sales and Distribution Channel Analysis

4.3.3. Downstream Buyer Analysis

Chapter 5. COVID 19 Impact on Australia Forklift Market

5.1. COVID-19 Landscape: Australia Forklift Industry Impact

5.2. COVID 19 - Impact Assessment for the Industry

5.3. COVID 19 Impact: Major Government Policy

5.4. Market Trends and Opportunities in the COVID-19 Landscape

Chapter 6. Market Dynamics Analysis and Trends

6.1. Market Dynamics

6.1.1. Market Drivers

6.1.2. Market Restraints

6.1.3. Market Opportunities

6.2. Porter’s Five Forces Analysis

6.2.1. Bargaining power of suppliers

6.2.2. Bargaining power of buyers

6.2.3. Threat of substitute

6.2.4. Threat of new entrants

6.2.5. Degree of competition

Chapter 7. Competitive Landscape

7.1.1. Company Market Share/Positioning Analysis

7.1.2. Key Strategies Adopted by Players

7.1.3. Vendor Landscape

7.1.3.1. List of Suppliers

7.1.3.2. List of Buyers

Chapter 8. Australia Forklift Market, By Tonnage Capacity

8.1. Australia Forklift Market, by Tonnage Capacity, 2023-2032

8.1.1. Below 5 Ton

8.1.1.1. Market Revenue and Forecast (2020-2032)

8.1.2. 6-30 Ton

8.1.2.1. Market Revenue and Forecast (2020-2032)

8.1.3. Above 30 Ton

8.1.3.1. Market Revenue and Forecast (2020-2032)

Chapter 9. Australia Forklift Market, By Class

9.1. Australia Forklift Market, by Class, 2023-2032

9.1.1. Class 1

9.1.1.1. Market Revenue and Forecast (2020-2032)

9.1.2. Class 2

9.1.2.1. Market Revenue and Forecast (2020-2032)

9.1.3. Class 3

9.1.3.1. Market Revenue and Forecast (2020-2032)

9.1.4. Class 4/5

9.1.4.1. Market Revenue and Forecast (2020-2032)

Chapter 10. Australia Forklift Market, By Power Source

10.1. Australia Forklift Market, by Power Source, 2023-2032

10.1.1. ICE

10.1.1.1. Market Revenue and Forecast (2020-2032)

10.1.2. Electric

10.1.2.1. Market Revenue and Forecast (2020-2032)

Chapter 11. Australia Forklift Market, By Product Type

11.1. Australia Forklift Market, by Product Type, 2023-2032

11.1.1. Warehouse

11.1.1.1. Market Revenue and Forecast (2020-2032)

11.1.2. Counterbalance

11.1.2.1. Market Revenue and Forecast (2020-2032)

Chapter 12. Australia Forklift Market, Regional Estimates and Trend Forecast

12.1. Australia

12.1.1. Market Revenue and Forecast, by Tonnage Capacity (2020-2032)

12.1.2. Market Revenue and Forecast, by Class (2020-2032)

12.1.3. Market Revenue and Forecast, by Power Source (2020-2032)

12.1.4. Market Revenue and Forecast, by Product Type (2020-2032)

Chapter 13. Company Profiles

13.1. CLARK

13.1.1. Company Overview

13.1.2. Product Offerings

13.1.3. Financial Performance

13.1.4. Recent Initiatives

13.2. Crown Equipment Corporation

13.2.1. Company Overview

13.2.2. Product Offerings

13.2.3. Financial Performance

13.2.4. Recent Initiatives

13.3. Doosan Corporation

13.3.1. Company Overview

13.3.2. Product Offerings

13.3.3. Financial Performance

13.3.4. Recent Initiatives

13.4. Hangcha

13.4.1. Company Overview

13.4.2. Product Offerings

13.4.3. Financial Performance

13.4.4. Recent Initiatives

13.5. Hyster-Yale Materials Handling, Inc.

13.5.1. Company Overview

13.5.2. Product Offerings

13.5.3. Financial Performance

13.5.4. Recent Initiatives

13.6. Jungheinrich AG

13.6.1. Company Overview

13.6.2. Product Offerings

13.6.3. Financial Performance

13.6.4. Recent Initiatives

13.7. Komatsu Ltd.

13.7.1. Company Overview

13.7.2. Product Offerings

13.7.3. Financial Performance

13.7.4. Recent Initiatives

13.8. Toyota Material Handling

13.8.1. Company Overview

13.8.2. Product Offerings

13.8.3. Financial Performance

13.8.4. Recent Initiatives

Chapter 14. Research Methodology

14.1. Primary Research

14.2. Secondary Research

14.3. Assumptions

Chapter 15. Appendix

15.1. About Us

15.2. Glossary of Terms

Cross-segment Market Size and Analysis for

Mentioned Segments

Cross-segment Market Size and Analysis for

Mentioned Segments

Additional Company Profiles (Upto 5 With No Cost)

Additional Company Profiles (Upto 5 With No Cost)

Additional Countries (Apart From Mentioned Countries)

Additional Countries (Apart From Mentioned Countries)

Country/Region-specific Report

Country/Region-specific Report

Go To Market Strategy

Go To Market Strategy

Region Specific Market Dynamics

Region Specific Market Dynamics Region Level Market Share

Region Level Market Share Import Export Analysis

Import Export Analysis Production Analysis

Production Analysis Others

Others