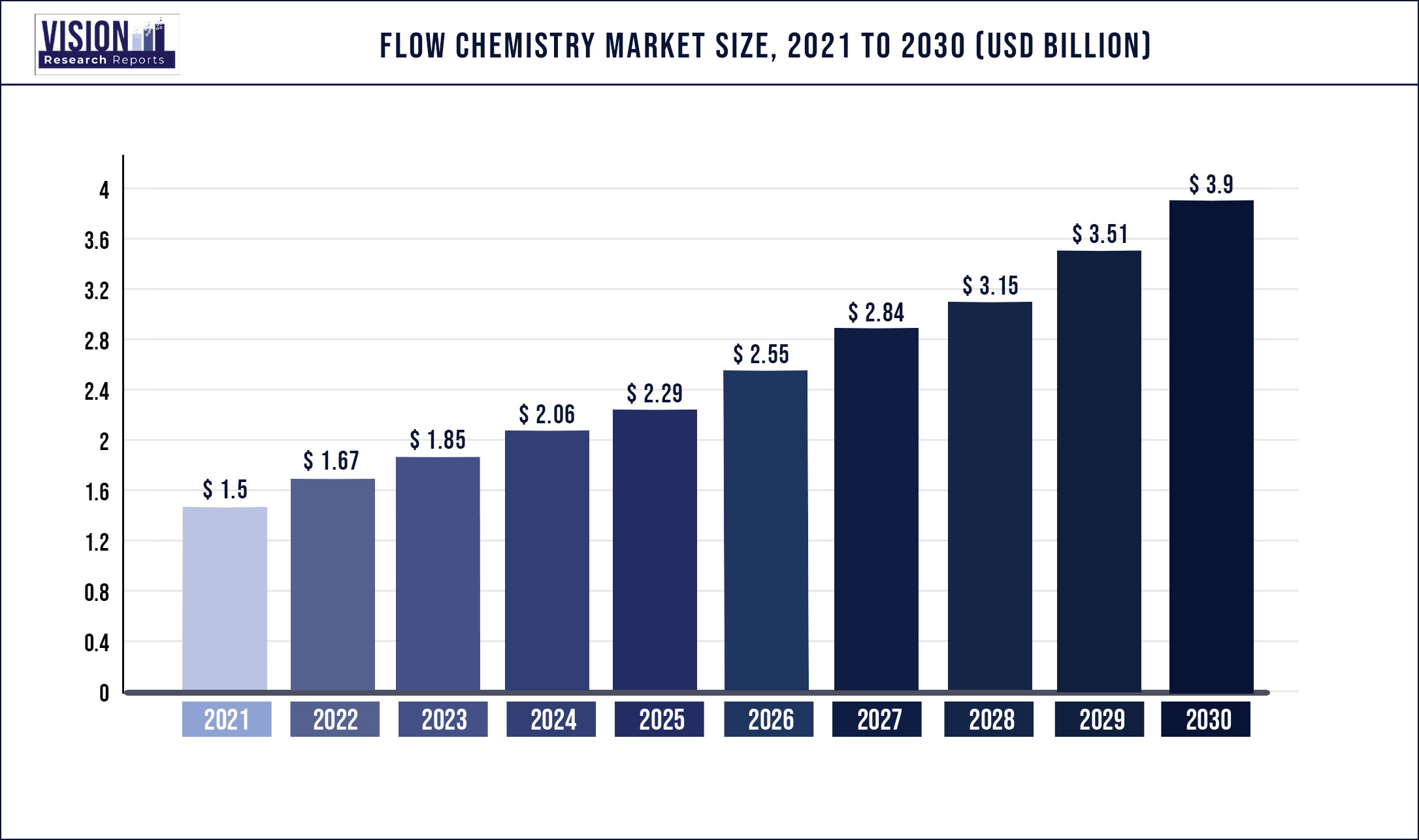

The global flow chemistry market was valued at USD 1.5 billion in 2021 and it is predicted to surpass around USD 3.9 billion by 2030 with a CAGR of 11.2% from 2022 to 2030.

Report Highlights

By reactor type, the U.S. flow chemistry market was valued at USD 411.3 million in 2021 and expected to witness growth at a CAGR of 10.1% from 2022 to 2030.

Advantages over batch reactors and growing investments in the pharmaceutical and chemical industries are projected to boost the market growth.

The COVID-19 pandemic has accelerated the need to move away from chemical commodities to specialty chemicals as per the requirement of customers. Moreover, the adoption of continuous manufacturing has increased due to the supply chain disruptions caused by the pandemic, which is expected to augment the demand for flow chemistry over the forecast period.

Significant reductions in trash output and the eradication of non-renewable industrial methods are global environmental concerns. As a result, major economies are enacting policies to mitigate environmental damage. Several governments are implementing policies to meet the targets for reducing greenhouse gas emissions.

Continuous Stirred Tank (CST) reactor systems require little human involvement to operate, resulting in reduced labor costs associated with their deployment. Furthermore, both reactor systems have a high output rate, which leads to reduced production costs. The aforementioned factors are likely to boost the demand for CST reactor systems over the forecast period.

The growing pharmaceutical industry has positively impacted the market for several years on account of the increase in the number of potent and orphan drugs. Moreover, the need for process safety, reduction of investment cost, and quality standards are likely to augment the demand for flow chemistry over the forecast period.

The growing use of microreactors in the specialized chemical, fine chemical, and other petrochemical industries has helped to significantly reduce environmental impact while also lowering manufacturing costs. Microreactors are used in the bulk chemicals industry to produce several chemicals such as styrene and Ethylene Oxide (EO), which is expected to boost the market growth.

Scope of The Report

| Report Coverage | Details |

| Market Size in 2021 | USD 1.5 billion |

| Revenue Forecast by 2030 | USD 3.9 billion |

| Growth rate from 2022 to 2030 | CAGR of 11.2% |

| Base Year | 2021 |

| Forecast Period | 2022 to 2030 |

| Segmentation | Application, reactor type, region |

| Companies Covered | Am Technology; CEM Corporation; Milestone Srl; Biotage AB; Syrris Ltd.; Vapourtec Ltd.; ThalesNano Inc.; Hel Group; Uniqsis Ltd.; Chemtrix BV; Ehrfeld Mikrotechnik BTS; Future Chemistry; Holding BV; Corning Incorporated; Cambridge Reactor Design Ltd.; PDC Machines Inc.; Parr Instrument Company |

Reactor Type Insights

CSTR led the market and accounted for over 35.11% share of the global revenue in 2021. Factors responsible for the segment growth are high adoption, simple construction, good temperature control, low cost, and adaptability to two-phase runs. Moreover, the increasing use of CSTR in water and wastewater applications is likely to boost industry growth.

Plug flow reactor, also known as tubular reactor, is one of the most commonly used reactors for gas phase reactions. The absence of moving parts, high conversion rate per reactor volume, simple mechanism, and low maintenance lead to a low overall cost of production from these reactors, which is likely to propel their demand.

Microreactor is estimated to expand at a lucrative CAGR of 17.88% from 2022 to 2030, in terms of revenue. The demand for microreactors in pharmaceutical and fine chemicals due to their low footprint, the requirement of less capital commitment, and safe processing of highly reactive and hazardous processes is expected to boost industry growth.

Microwave-assisted organic synthesis has witnessed significant focus over the past years on account of its fast reaction rate, low byproducts and high yield, high purity of the products, easy scale-up, and ease of use. Microwave-assisted continuous reactors have been utilized mainly for academia and laboratory applications due to size limitations.

Application Insights

The chemicals segment led the market and accounted for over 35.09% share of the global revenue in 2021 on account of the increased use of environmentally-friendly technologies such as flow chemistry in order to reduce greenhouse emissions. Moreover, an increase in the demand for specialty chemicals from the automotive industry is expected to positively impact industry growth.

Numerous companies in the pharmaceutical industry have been trying to maintain collaboration between the industry and academic sectors. The academia and research segment is likely to introduce new methodologies for manufacturing chemicals and APIs, which is expected to augment the demand for reactors in this segment over the forecast period.

The pharmaceuticals application segment is expected to expand at a significant CAGR of 12.0% over the forecast period. Factors such as increasing demand for the optimization of drug development and demand to reduce the time taken for drug launch are expected to boost the demand for this equipment in pharmaceutical applications.

Other applications include fragrances, biofuels, and nanoparticle production. The use of continuous manufacturing in biofuels is slowly receiving preference as flow chemistry in the transesterification process can reduce time and cost, resulting in high production and profit and an increase in demand for flow chemistry.

Regional Insights

North America led the market and accounted for over 35.18% share of the global revenue in 2021. The increase in chemical and pharmaceutical production and a rise in investments in research and development in flow chemistry, especially in continuous processes, are some of the key factors fueling the industry growth in the region.

The APAC region is estimated to expand at the highest CAGR of 12.5% over the forecast period. An increase in government expenditure on pharmaceutical production due to an increase in demand for generic drugs, coupled with the promising outlook for the chemical and petrochemical industries, is likely to augment industry growth in the region.

The pharmaceutical industry in Europe is focusing on medical R&D by maintaining, sustaining, and developing a robust regulatory and innovation-supportive incentives environment. Flow chemistry makes the production of drugs economic and easy, resulting in the increased adoption of this technology by various pharmaceutical manufacturers across Europe.

An increase in oil production and increasing investments in the pharmaceutical industry in Brazil are expected to positively impact this industry in the country. Increasing focus on the field of biotechnology and rising adoption of green production processes are also likely to augment the industry growth in the country.

Key Players

Market Segmentation

Chapter 1. Introduction

1.1. Research Objective

1.2. Scope of the Study

1.3. Definition

Chapter 2. Research Methodology

2.1. Research Approach

2.2. Data Sources

2.3. Assumptions & Limitations

Chapter 3. Executive Summary

3.1. Market Snapshot

Chapter 4. Market Variables and Scope

4.1. Introduction

4.2. Market Classification and Scope

4.3. Industry Value Chain Analysis

4.3.1. Raw Material Procurement Analysis

4.3.2. Sales and Distribution Channel Analysis

4.3.3. Downstream Buyer Analysis

Chapter 5. COVID 19 Impact on Flow Chemistry Market

5.1. COVID-19 Landscape: Flow Chemistry Industry Impact

5.2. COVID 19 - Impact Assessment for the Industry

5.3. COVID 19 Impact: Global Major Government Policy

5.4. Market Trends and Opportunities in the COVID-19 Landscape

Chapter 6. Market Dynamics Analysis and Trends

6.1. Market Dynamics

6.1.1. Market Drivers

6.1.2. Market Restraints

6.1.3. Market Opportunities

6.2. Porter’s Five Forces Analysis

6.2.1. Bargaining power of suppliers

6.2.2. Bargaining power of buyers

6.2.3. Threat of substitute

6.2.4. Threat of new entrants

6.2.5. Degree of competition

Chapter 7. Competitive Landscape

7.1.1. Company Market Share/Positioning Analysis

7.1.2. Key Strategies Adopted by Players

7.1.3. Vendor Landscape

7.1.3.1. List of Suppliers

7.1.3.2. List of Buyers

Chapter 8. Global Flow Chemistry Market, By Application

8.1. Flow Chemistry Market, by Application, 2022-2030

8.1.1. Pharmaceuticals

8.1.1.1. Market Revenue and Forecast (2017-2030)

8.1.2. Chemicals

8.1.2.1. Market Revenue and Forecast (2017-2030)

8.1.3. Academia & Research

8.1.3.1. Market Revenue and Forecast (2017-2030)

8.1.4. Petrochemicals

8.1.4.1. Market Revenue and Forecast (2017-2030)

8.1.5. Others

8.1.5.1. Market Revenue and Forecast (2017-2030)

Chapter 9. Global Flow Chemistry Market, By Reactor Type

9.1. Flow Chemistry Market, by Reactor Type, 2022-2030

9.1.1. CSTR (Continuous stirred-tank reactor)

9.1.1.1. Market Revenue and Forecast (2017-2030)

9.1.2. Plug Flow Reactor

9.1.2.1. Market Revenue and Forecast (2017-2030)

9.1.3. Microreactor

9.1.3.1. Market Revenue and Forecast (2017-2030)

9.1.4. Microwave Systems

9.1.4.1. Market Revenue and Forecast (2017-2030)

9.1.5. Others

9.1.5.1. Market Revenue and Forecast (2017-2030)

Chapter 10. Global Flow Chemistry Market, Regional Estimates and Trend Forecast

10.1. North America

10.1.1. Market Revenue and Forecast, by Application (2017-2030)

10.1.2. Market Revenue and Forecast, by Reactor Type (2017-2030)

10.1.3. U.S.

10.1.3.1. Market Revenue and Forecast, by Application (2017-2030)

10.1.3.2. Market Revenue and Forecast, by Reactor Type (2017-2030)

10.1.4. Rest of North America

10.1.4.1. Market Revenue and Forecast, by Application (2017-2030)

10.1.4.2. Market Revenue and Forecast, by Reactor Type (2017-2030)

10.2. Europe

10.2.1. Market Revenue and Forecast, by Application (2017-2030)

10.2.2. Market Revenue and Forecast, by Reactor Type (2017-2030)

10.2.3. UK

10.2.3.1. Market Revenue and Forecast, by Application (2017-2030)

10.2.3.2. Market Revenue and Forecast, by Reactor Type (2017-2030)

10.2.4. Germany

10.2.4.1. Market Revenue and Forecast, by Application (2017-2030)

10.2.4.2. Market Revenue and Forecast, by Reactor Type (2017-2030)

10.2.5. France

10.2.5.1. Market Revenue and Forecast, by Application (2017-2030)

10.2.5.2. Market Revenue and Forecast, by Reactor Type (2017-2030)

10.2.6. Rest of Europe

10.2.6.1. Market Revenue and Forecast, by Application (2017-2030)

10.2.6.2. Market Revenue and Forecast, by Reactor Type (2017-2030)

10.3. APAC

10.3.1. Market Revenue and Forecast, by Application (2017-2030)

10.3.2. Market Revenue and Forecast, by Reactor Type (2017-2030)

10.3.3. India

10.3.3.1. Market Revenue and Forecast, by Application (2017-2030)

10.3.3.2. Market Revenue and Forecast, by Reactor Type (2017-2030)

10.3.4. China

10.3.4.1. Market Revenue and Forecast, by Application (2017-2030)

10.3.4.2. Market Revenue and Forecast, by Reactor Type (2017-2030)

10.3.5. Japan

10.3.5.1. Market Revenue and Forecast, by Application (2017-2030)

10.3.5.2. Market Revenue and Forecast, by Reactor Type (2017-2030)

10.3.6. Rest of APAC

10.3.6.1. Market Revenue and Forecast, by Application (2017-2030)

10.3.6.2. Market Revenue and Forecast, by Reactor Type (2017-2030)

10.4. MEA

10.4.1. Market Revenue and Forecast, by Application (2017-2030)

10.4.2. Market Revenue and Forecast, by Reactor Type (2017-2030)

10.4.3. GCC

10.4.3.1. Market Revenue and Forecast, by Application (2017-2030)

10.4.3.2. Market Revenue and Forecast, by Reactor Type (2017-2030)

10.4.4. North Africa

10.4.4.1. Market Revenue and Forecast, by Application (2017-2030)

10.4.4.2. Market Revenue and Forecast, by Reactor Type (2017-2030)

10.4.5. South Africa

10.4.5.1. Market Revenue and Forecast, by Application (2017-2030)

10.4.5.2. Market Revenue and Forecast, by Reactor Type (2017-2030)

10.4.6. Rest of MEA

10.4.6.1. Market Revenue and Forecast, by Application (2017-2030)

10.4.6.2. Market Revenue and Forecast, by Reactor Type (2017-2030)

10.5. Latin America

10.5.1. Market Revenue and Forecast, by Application (2017-2030)

10.5.2. Market Revenue and Forecast, by Reactor Type (2017-2030)

10.5.3. Brazil

10.5.3.1. Market Revenue and Forecast, by Application (2017-2030)

10.5.3.2. Market Revenue and Forecast, by Reactor Type (2017-2030)

10.5.4. Rest of LATAM

10.5.4.1. Market Revenue and Forecast, by Application (2017-2030)

10.5.4.2. Market Revenue and Forecast, by Reactor Type (2017-2030)

Chapter 11. Company Profiles

11.1. Am Technology

11.1.1. Company Overview

11.1.2. Product Offerings

11.1.3. Financial Performance

11.1.4. Recent Initiatives

11.2. CEM Corporation

11.2.1. Company Overview

11.2.2. Product Offerings

11.2.3. Financial Performance

11.2.4. Recent Initiatives

11.3. Milestone Srl

11.3.1. Company Overview

11.3.2. Product Offerings

11.3.3. Financial Performance

11.3.4. Recent Initiatives

11.4. Biotage AB

11.4.1. Company Overview

11.4.2. Product Offerings

11.4.3. Financial Performance

11.4.4. Recent Initiatives

11.5. Syrris Ltd.

11.5.1. Company Overview

11.5.2. Product Offerings

11.5.3. Financial Performance

11.5.4. Recent Initiatives

11.6. Vapourtec Ltd.

11.6.1. Company Overview

11.6.2. Product Offerings

11.6.3. Financial Performance

11.6.4. Recent Initiatives

11.7. ThalesNano Inc.

11.7.1. Company Overview

11.7.2. Product Offerings

11.7.3. Financial Performance

11.7.4. Recent Initiatives

11.8. Hel Group

11.8.1. Company Overview

11.8.2. Product Offerings

11.8.3. Financial Performance

11.8.4. Recent Initiatives

11.9. Uniqsis Ltd.

11.9.1. Company Overview

11.9.2. Product Offerings

11.9.3. Financial Performance

11.9.4. Recent Initiatives

11.10. Chemtrix BV

11.10.1. Company Overview

11.10.2. Product Offerings

11.10.3. Financial Performance

11.10.4. Recent Initiatives

Chapter 12. Research Methodology

12.1. Primary Research

12.2. Secondary Research

12.3. Assumptions

Chapter 13. Appendix

13.1. About Us

13.2. Glossary of Terms

Cross-segment Market Size and Analysis for

Mentioned Segments

Cross-segment Market Size and Analysis for

Mentioned Segments

Additional Company Profiles (Upto 5 With No Cost)

Additional Company Profiles (Upto 5 With No Cost)

Additional Countries (Apart From Mentioned Countries)

Additional Countries (Apart From Mentioned Countries)

Country/Region-specific Report

Country/Region-specific Report

Go To Market Strategy

Go To Market Strategy

Region Specific Market Dynamics

Region Specific Market Dynamics Region Level Market Share

Region Level Market Share Import Export Analysis

Import Export Analysis Production Analysis

Production Analysis Others

Others