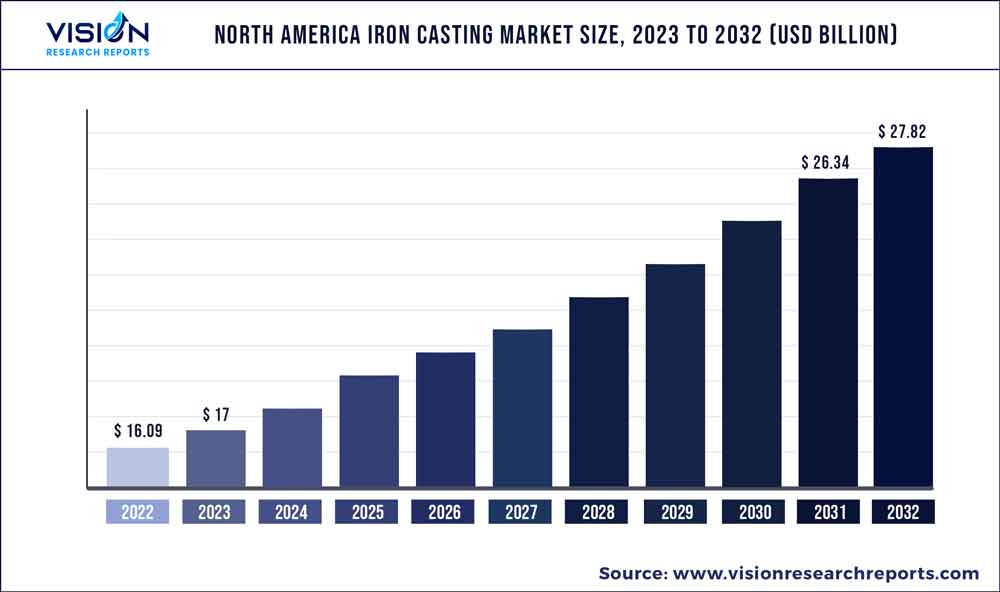

The North America iron casting market was surpassed at USD 16.09 billion in 2022 and is expected to hit around USD 27.82 billion by 2032, growing at a CAGR of 5.63% from 2023 to 2032.

Key Pointers

| Report Coverage | Details |

| Market Size in 2022 | USD 16.09 billion |

| Revenue Forecast by 2032 | USD 27.82 billion |

| Growth rate from 2023 to 2032 | CAGR of 5.63% |

| Base Year | 2022 |

| Forecast Period | 2023 to 2032 |

| Market Analysis (Terms Used) | Value (US$ Million/Billion) or (Volume/Units) |

| Companies Covered | Cadillac Casting Inc.; CALMET; Decatur Foundry; Fusium; Grupo Industrial Saltillo (GIS); Hitachi Metals; Ltd.; GREDE; Lemfco, Inc; OSCO Industries, Inc; Neenah Foundry; US Castings; WAUPACA FOUNDRY; INC.; Alloy Casting Industries Ltd. |

Growing investments in the railway sector toward economic development across various countries are anticipated to drive market growth over the coming years. Due to their high strength and low wear characteristics, iron castings are used in the production of components for railroads & their infrastructure. Thus, rising investment in the railway sector is anticipated to propel product demand over the forecast period. For instance, in March 2022, the Government of Mexico unveiled its USD 2.4 billion metro modernization plan. The upgradation of the infrastructure is expected to be completed by 2030.

The U.S. is a significant market for iron castings owing to the widespread presence of end-use industries. The product demand in the country is being driven by large-scale auto plants, manufacturers of machinery & tools, and increasing demand for pipes and fittings due to the development of the petrochemical industry and infrastructure improvements.

Growing investments in setting up new plants for water and sewage treatment are further anticipated to augment market growth in the coming years. For instance, in November 2021, Haskell was selected to design and build a new water treatment plant worth USD 150 million in Riviera Beach, U.S. The plant is expected to be functional by 2023.

Furthermore, growing infrastructural developments are expected to fuel the need for iron castings. For instance, a USD 1 trillion bipartisan plan to upgrade the nation's infrastructure, including its roads, bridges, airports, rail networks, and power systems, was approved by the U.S. government in November 2021. This infrastructure upgrade is expected to be finished by 2025.

Iron castings have been widely used by the automotive industry. However, the consistent decline in global vehicle production over the past few years has been a challenge for the market. Also, the growing inclination towards lightweight vehicles is propelling the penetration of aluminum castings in the automotive industry, which is restraining the market growth.

Product Insights

Based on product, gray cast iron accounted for the largest revenue share of over 60.05% in 2022 of the overall market. It is largely used due to its high compressive strength, good damping capacity, high thermal conductivity, good machinability, low-cost production, and good wear resistance. These properties make the product applicable in a variety of applications including pipes, machinery & tools, and automobiles.

Increasing demand for machines & tooling is pushing key manufacturers to set up new plants, which are expected to boost segment growth over the forecast period. For instance, in September 2022, Seco Tools opened a new tool manufacturing unit in Ramos Arizpe, Mexico. The plant spans over 2,500 square meters.

Ductile cast iron is expected to register the fastest CAGR of 5.92% in terms of revenue over the forecast period. Due to its lower density and exceptional reliability, even at extremely low temperatures, the product is chosen by manufacturers of wind energy power plants and various machine & tooling parts. Furthermore, owing to its microstructure, it finds application in water & sewage pipes.

Malleable cast iron is another vital segment of the market. It produces stronger castings, which makes it suitable for applications requiring high machinability and toughness. It finds wide usage in a variety of sectors, including agriculture, machinery, automotive, and mining.

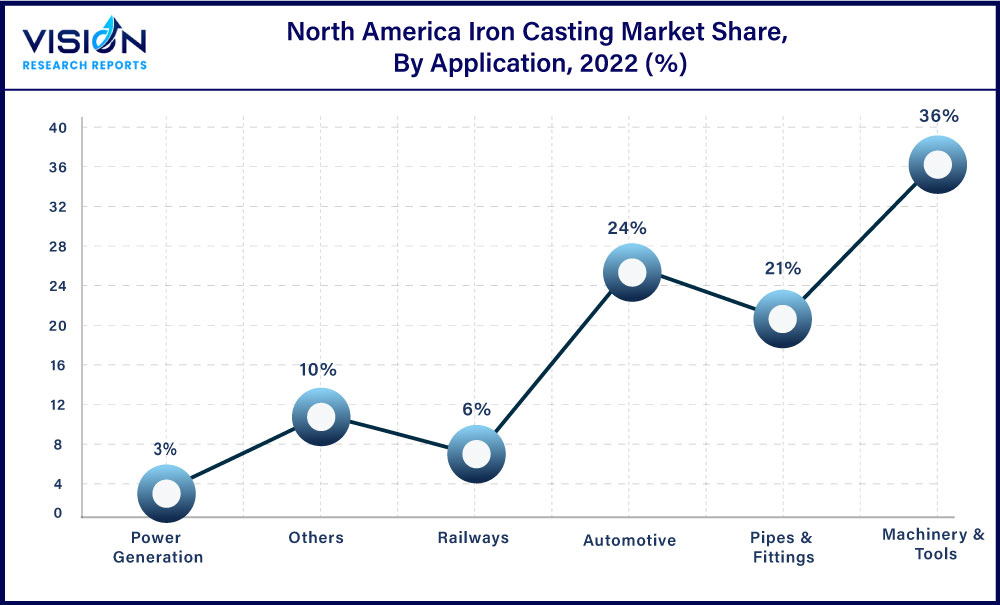

Application Insights

The machinery & tools segment held the largest revenue share of over 36% in the year 2022 in the overall market, and it is expected to continue its dominance across the forecast period. Iron castings are widely used in machinery & tools owing to their good wear resistance, high strength, and good machinability. These are used for producing machinery and tools used in industrial, construction, and agriculture/farming applications.

Rising demand for machine tools for increasing productivity is expected to fuel segment growth over the coming years. For instance, according to the U.S. Manufacturing Technology Orders Report, the new orders of manufacturing technology reached USD 467.8 million in February 2023, which is 33% more than the previous month. This value for February 2023 is 50% above the average value for all February orders. The rise in demand for machine tools is fueled by increased spending on manufacturing technologies.

The railway sector is anticipated to register the fastest CAGR in terms of revenue over the forecast period. Increasing investments by several governments to modernize their rail infrastructure is expected to propel the demand for iron castings. For instance, in March 2021, the U.S. proposed a plan to invest USD 80 billion in passenger and freight rail services. The investment intends to modernize the Northeast corridor.

Iron castings are used in water and sewage pipes owing to their good compression strength and long life. They are more energy efficient than other alternatives such as polyvinyl chloride (PVC), cross-linked polyethylene (PEX), and copper, owing to their oversized inside diameter. Large diameter enables cast iron pipes to reduce the force required to push water through the pipes.

North America Iron Casting Market Segmentations:

By Product

By Application

Chapter 1. Introduction

1.1. Research Objective

1.2. Scope of the Study

1.3. Definition

Chapter 2. Research Methodology

2.1. Research Approach

2.2. Data Sources

2.3. Assumptions & Limitations

Chapter 3. Executive Summary

3.1. Market Snapshot

Chapter 4. Market Variables and Scope

4.1. Introduction

4.2. Market Classification and Scope

4.3. Industry Value Chain Analysis

4.3.1. Raw Material Procurement Analysis

4.3.2. Sales and Distribution Channel Analysis

4.3.3. Downstream Buyer Analysis

Chapter 5. COVID 19 Impact on North America Iron Casting Market

5.1. COVID-19 Landscape: North America Iron Casting Industry Impact

5.2. COVID 19 - Impact Assessment for the Industry

5.3. COVID 19 Impact: Major Government Policy

5.4. Market Trends and Opportunities in the COVID-19 Landscape

Chapter 6. Market Dynamics Analysis and Trends

6.1. Market Dynamics

6.1.1. Market Drivers

6.1.2. Market Restraints

6.1.3. Market Opportunities

6.2. Porter’s Five Forces Analysis

6.2.1. Bargaining power of suppliers

6.2.2. Bargaining power of buyers

6.2.3. Threat of substitute

6.2.4. Threat of new entrants

6.2.5. Degree of competition

Chapter 7. Competitive Landscape

7.1.1. Company Market Share/Positioning Analysis

7.1.2. Key Strategies Adopted by Players

7.1.3. Vendor Landscape

7.1.3.1. List of Suppliers

7.1.3.2. List of Buyers

Chapter 8. North America Iron Casting Market, By Product

8.1. North America Iron Casting Market, by Product, 2023-2032

8.1.1. Gray Cast Iron

8.1.1.1. Market Revenue and Forecast (2020-2032)

8.1.2. Ductile Cast Iron

8.1.2.1. Market Revenue and Forecast (2020-2032)

8.1.3. Malleable Cast Iron

8.1.3.1. Market Revenue and Forecast (2020-2032)

Chapter 9. North America Iron Casting Market, By Application

9.1. North America Iron Casting Market, by Application, 2023-2032

9.1.1. Automotive

9.1.1.1. Market Revenue and Forecast (2020-2032)

9.1.2. Machinery & Tools

9.1.2.1. Market Revenue and Forecast (2020-2032)

9.1.3. Pipes & Fittings

9.1.3.1. Market Revenue and Forecast (2020-2032)

9.1.4. Railways

9.1.4.1. Market Revenue and Forecast (2020-2032)

9.1.5. Power Generation

9.1.5.1. Market Revenue and Forecast (2020-2032)

9.1.6. Others

9.1.6.1. Market Revenue and Forecast (2020-2032)

Chapter 10. North America Iron Casting Market, Regional Estimates and Trend Forecast

10.1. North America

10.1.1. Market Revenue and Forecast, by Product (2020-2032)

10.1.2. Market Revenue and Forecast, by Application (2020-2032)

Chapter 11. Company Profiles

11.1. Cadillac Casting Inc.

11.1.1. Company Overview

11.1.2. Product Offerings

11.1.3. Financial Performance

11.1.4. Recent Initiatives

11.2. CALMET

11.2.1. Company Overview

11.2.2. Product Offerings

11.2.3. Financial Performance

11.2.4. Recent Initiatives

11.3. Decatur Foundry

11.3.1. Company Overview

11.3.2. Product Offerings

11.3.3. Financial Performance

11.3.4. Recent Initiatives

11.4. Fusium

11.4.1. Company Overview

11.4.2. Product Offerings

11.4.3. Financial Performance

11.4.4. LTE Scientific

11.5. Grupo Industrial Saltillo (GIS)

11.5.1. Company Overview

11.5.2. Product Offerings

11.5.3. Financial Performance

11.5.4. Recent Initiatives

11.6. Hitachi Metals

11.6.1. Company Overview

11.6.2. Product Offerings

11.6.3. Financial Performance

11.6.4. Recent Initiatives

11.7. Ltd

11.7.1. Company Overview

11.7.2. Product Offerings

11.7.3. Financial Performance

11.7.4. Recent Initiatives

11.8. GREDE

11.8.1. Company Overview

11.8.2. Product Offerings

11.8.3. Financial Performance

11.8.4. Recent Initiatives

11.9. Lemfco, Inc

11.9.1. Company Overview

11.9.2. Product Offerings

11.9.3. Financial Performance

11.9.4. Recent Initiatives

11.10. OSCO Industries, Inc

11.10.1. Company Overview

11.10.2. Product Offerings

11.10.3. Financial Performance

11.10.4. Recent Initiatives

Chapter 12. Research Methodology

12.1. Primary Research

12.2. Secondary Research

12.3. Assumptions

Chapter 13. Appendix

13.1. About Us

13.2. Glossary of Terms

Cross-segment Market Size and Analysis for

Mentioned Segments

Cross-segment Market Size and Analysis for

Mentioned Segments

Additional Company Profiles (Upto 5 With No Cost)

Additional Company Profiles (Upto 5 With No Cost)

Additional Countries (Apart From Mentioned Countries)

Additional Countries (Apart From Mentioned Countries)

Country/Region-specific Report

Country/Region-specific Report

Go To Market Strategy

Go To Market Strategy

Region Specific Market Dynamics

Region Specific Market Dynamics Region Level Market Share

Region Level Market Share Import Export Analysis

Import Export Analysis Production Analysis

Production Analysis Others

Others