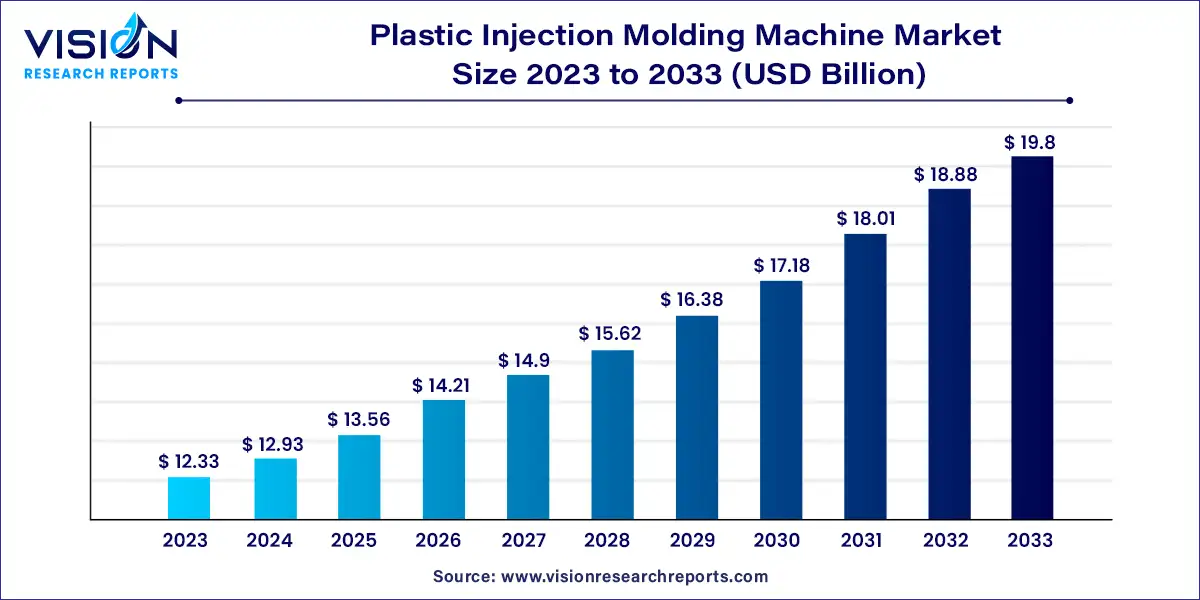

The global plastic injection molding machine market size was estimated at around USD 12.33 billion in 2023 and it is projected to hit around USD 19.8 billion by 2033, growing at a CAGR of 4.85% from 2024 to 2033.

The plastic injection molding machine market encompasses a wide array of machines utilized in the production of plastic components across various industries. These machines serve a critical role in the manufacturing process by injecting molten plastic into a mold to create a desired shape.

The growth of the plastic injection molding machine market is propelled by an increasing demand from diverse end-use industries such as automotive, packaging, electronics, healthcare, and consumer goods drives market expansion. Secondly, ongoing technological advancements in machine efficiency, precision, and automation contribute to market growth by enhancing manufacturing capabilities. Additionally, the rising trend of customization in product design fuels demand for injection molding machines capable of producing tailored components. Moreover, the shift towards lightweight, durable, and cost-effective plastic components in various applications further boosts market growth. These growth factors collectively indicate a promising trajectory for the plastic injection molding machine market, with continued opportunities for innovation and expansion.

| Report Coverage | Details |

| Revenue Share of Asia Pacific in 2023 | 40% |

| CAGR of Central and South America from 2024 to 2033 | 5.15% |

| Revenue Forecast by 2033 | USD 19.8 billion |

| Growth Rate from 2024 to 2033 | CAGR of 4.85% |

| Base Year | 2023 |

| Forecast Period | 2024 to 2033 |

| Market Analysis (Terms Used) | Value (US$ Million/Billion) or (Volume/Units) |

The hydraulic technology segment dominated the market in 2023 with the largest share of 54% in terms of revenue. The segment is expected to grow because of factors such as the ability to produce large quantities of parts, intricate parts for the automotive industry, lower initial costs, production of precise molds, higher wear and tear resistance of hydraulic parts, and widespread use in the automotive, marine, and aerospace industries where heavy force is required.

Electric plastic injection molding machine is anticipated to grow at the fastest CAGR of 5.57% from 2024 to 2033. These machines are highly efficient and require less start-up time and run-time compared to their hydraulic equivalents. Electric plastic injection molding machines use 50% to 75% less energy on average than their hydraulic equivalents because they are tighter, faster, cleaner, and repeatable process production equipment with little waste.

Electric plastic injection molding machines are run by digitally controlled servo motors with high speeds, aiding precise, faster, energy-efficient, and repeatable operations. The plastic injection molding process is predictable and can be replicated consistently, thereby providing high-quality components. Furthermore, with increased automated machines, the requirement for labor has been reduced, which in turn, is lowering labor costs and increasing profit margins.

A hybrid plastic injection molding machine combines the best of both hydraulic and electric injection molding machines. A hybrid injection molding machine offers high clamping force of the hydraulic machines and high precision, energy efficiency, reduced noise, and repeatability of the electric injection molding machines, leading to better performance for both thick- and thin-walled parts.

The automotive end-use segment dominated the plastic injection molding market in 2023 with the largest revenue share of 31% owing to factors such as material compatibility, high precision, repeatability, and surface finish. Furthermore, increasing demand for lightweight automotive components and rising automotive production are expected to propel market growth.

In the automotive industry, plastic injection molding machines are used to manufacture the most complex-shaped critical parts. A plastic injection molding machine is used to produce a variety of automotive parts such as bumpers, electrical housings, exterior body panels, and dashboards. Injection molding machines are used in the automotive industry for manufacturing exterior parts such as door panels, car door trim, bumpers, trunk trims rear & front covering, floor rails, sensor holders, grilles, wheel arches, and fenders/mudguards. These aforementioned factors are anticipated to propel market growth throughout the forecast period.

The medical segment is anticipated to grow at the fastest CAGR of 5.94% over the forecast period. Plastic injection molding machines are used in the medical industry for manufacturing small and complex items such as dental implants, prosthetic replacements, endoscopic tools, tweezers, scissors, implantable components, orthopedics, and drug delivery equipment. The increasing demand for medical disposables, technological developments, and rising plastic consumption in healthcare applications are driving the industry growth for the plastic injection molding machine industry.

Plastic injection molding machine is used to manufacture consumer goods such as personal hygiene products, houseware, travel accessories, furniture, toys, cosmetics, and convenience goods. In the past few years, most traditional materials such as glass, wood, and metal are being replaced by high-quality plastics, thereby augmenting the demand for plastic injection molding machines.

The Asia Pacific region dominated the market in 2023 with the largest share of 40% in terms of revenue owing to the massive investments by the governments of different countries in the region for the development of public infrastructure and expansion of residential construction. Furthermore, there is rising awareness regarding energy saving globally, which is expected to further augment the market demand.

Growing demand for on-the-go packaged products owing to increasing purchasing power and busy lifestyle in the North America region is expected to have a positive impact on the packaging industry growth in the region. A plastic injection molding machine is used for manufacturing various packaging products such as containers, bottles, caps & closures, and covers. Growth in the packaging industry coupled with the rising adoption of plastic injection molding machines in this region for manufacturing packaging products is expected to drive market growth.

Europe held the second-largest revenue share in the market in 2023. The flourishing electronics sector, primarily due to the growing adoption of flexible electronics in Europe, has led to a new application scope in the region. The plastic injection molding machine is used to manufacture electronic components such as sensors, meters, testing equipment, electronic connectors, and processing equipment. The flourishing electronics industry in the region is anticipated to contribute to the growth of the market in Europe over the forecast period.

During the projected period, Central and South America are expected to grow at a CAGR of 5.15%. Demand for plastic injection molding machines is anticipated to witness substantial growth owing to the increasing demand for manufacturing facilities in the emerging economies of the region. This is projected to have a positive impact on industrial construction, thereby boosting the industry demand over the forecast period.

By Technology

By End-use

By Region

Chapter 1. Introduction

1.1. Research Objective

1.2. Scope of the Study

1.3. Definition

Chapter 2. Research Methodology

2.1. Research Approach

2.2. Data Sources

2.3. Assumptions & Limitations

Chapter 3. Executive Summary

3.1. Market Snapshot

Chapter 4. Market Variables and Scope

4.1. Introduction

4.2. Market Classification and Scope

4.3. Industry Value Chain Analysis

4.3.1. Raw Material Procurement Analysis

4.3.2. Sales and Distribution Channel Analysis

4.3.3. Downstream Buyer Analysis

Chapter 5. COVID 19 Impact on Plastic Injection Molding Machine Market

5.1. COVID-19 Landscape: Plastic Injection Molding Machine Industry Impact

5.2. COVID 19 - Impact Assessment for the Industry

5.3. COVID 19 Impact: Global Major Government Policy

5.4. Market Trends and Opportunities in the COVID-19 Landscape

Chapter 6. Market Dynamics Analysis and Trends

6.1. Market Dynamics

6.1.1. Market Drivers

6.1.2. Market Restraints

6.1.3. Market Opportunities

6.2. Porter’s Five Forces Analysis

6.2.1. Bargaining power of suppliers

6.2.2. Bargaining power of buyers

6.2.3. Threat of substitute

6.2.4. Threat of new entrants

6.2.5. Degree of competition

Chapter 7. Competitive Landscape

7.1.1. Company Market Share/Positioning Analysis

7.1.2. Key Strategies Adopted by Players

7.1.3. Vendor Landscape

7.1.3.1. List of Suppliers

7.1.3.2. List of Buyers

Chapter 8. Global Plastic Injection Molding Machine Market, By Technology

8.1. Plastic Injection Molding Machine Market, by Technology, 2024-2033

8.1.1. Hydraulic

8.1.1.1. Market Revenue and Forecast (2021-2033)

8.1.2. Electric

8.1.2.1. Market Revenue and Forecast (2021-2033)

8.1.3. Hybrid

8.1.3.1. Market Revenue and Forecast (2021-2033)

Chapter 9. Global Plastic Injection Molding Machine Market, By End-use

9.1. Plastic Injection Molding Machine Market, by End-use, 2024-2033

9.1.1. Automotive

9.1.1.1. Market Revenue and Forecast (2021-2033)

9.1.2. Consumer Goods

9.1.2.1. Market Revenue and Forecast (2021-2033)

9.1.3. Packaging

9.1.3.1. Market Revenue and Forecast (2021-2033)

9.1.4. Electronics

9.1.4.1. Market Revenue and Forecast (2021-2033)

9.1.5. Construction

9.1.5.1. Market Revenue and Forecast (2021-2033)

9.1.6. Medical

9.1.6.1. Market Revenue and Forecast (2021-2033)

9.1.7. Others

9.1.7.1. Market Revenue and Forecast (2021-2033)

Chapter 10. Global Plastic Injection Molding Machine Market, Regional Estimates and Trend Forecast

10.1. North America

10.1.1. Market Revenue and Forecast, by Technology (2021-2033)

10.1.2. Market Revenue and Forecast, by End-use (2021-2033)

10.1.3. U.S.

10.1.3.1. Market Revenue and Forecast, by Technology (2021-2033)

10.1.3.2. Market Revenue and Forecast, by End-use (2021-2033)

10.1.4. Rest of North America

10.1.4.1. Market Revenue and Forecast, by Technology (2021-2033)

10.1.4.2. Market Revenue and Forecast, by End-use (2021-2033)

10.2. Europe

10.2.1. Market Revenue and Forecast, by Technology (2021-2033)

10.2.2. Market Revenue and Forecast, by End-use (2021-2033)

10.2.3. UK

10.2.3.1. Market Revenue and Forecast, by Technology (2021-2033)

10.2.3.2. Market Revenue and Forecast, by End-use (2021-2033)

10.2.4. Germany

10.2.4.1. Market Revenue and Forecast, by Technology (2021-2033)

10.2.4.2. Market Revenue and Forecast, by End-use (2021-2033)

10.2.5. France

10.2.5.1. Market Revenue and Forecast, by Technology (2021-2033)

10.2.5.2. Market Revenue and Forecast, by End-use (2021-2033)

10.2.6. Rest of Europe

10.2.6.1. Market Revenue and Forecast, by Technology (2021-2033)

10.2.6.2. Market Revenue and Forecast, by End-use (2021-2033)

10.3. APAC

10.3.1. Market Revenue and Forecast, by Technology (2021-2033)

10.3.2. Market Revenue and Forecast, by End-use (2021-2033)

10.3.3. India

10.3.3.1. Market Revenue and Forecast, by Technology (2021-2033)

10.3.3.2. Market Revenue and Forecast, by End-use (2021-2033)

10.3.4. China

10.3.4.1. Market Revenue and Forecast, by Technology (2021-2033)

10.3.4.2. Market Revenue and Forecast, by End-use (2021-2033)

10.3.5. Japan

10.3.5.1. Market Revenue and Forecast, by Technology (2021-2033)

10.3.5.2. Market Revenue and Forecast, by End-use (2021-2033)

10.3.6. Rest of APAC

10.3.6.1. Market Revenue and Forecast, by Technology (2021-2033)

10.3.6.2. Market Revenue and Forecast, by End-use (2021-2033)

10.4. MEA

10.4.1. Market Revenue and Forecast, by Technology (2021-2033)

10.4.2. Market Revenue and Forecast, by End-use (2021-2033)

10.4.3. GCC

10.4.3.1. Market Revenue and Forecast, by Technology (2021-2033)

10.4.3.2. Market Revenue and Forecast, by End-use (2021-2033)

10.4.4. North Africa

10.4.4.1. Market Revenue and Forecast, by Technology (2021-2033)

10.4.4.2. Market Revenue and Forecast, by End-use (2021-2033)

10.4.5. South Africa

10.4.5.1. Market Revenue and Forecast, by Technology (2021-2033)

10.4.5.2. Market Revenue and Forecast, by End-use (2021-2033)

10.4.6. Rest of MEA

10.4.6.1. Market Revenue and Forecast, by Technology (2021-2033)

10.4.6.2. Market Revenue and Forecast, by End-use (2021-2033)

10.5. Latin America

10.5.1. Market Revenue and Forecast, by Technology (2021-2033)

10.5.2. Market Revenue and Forecast, by End-use (2021-2033)

10.5.3. Brazil

10.5.3.1. Market Revenue and Forecast, by Technology (2021-2033)

10.5.3.2. Market Revenue and Forecast, by End-use (2021-2033)

10.5.4. Rest of LATAM

10.5.4.1. Market Revenue and Forecast, by Technology (2021-2033)

10.5.4.2. Market Revenue and Forecast, by End-use (2021-2033)

Chapter 11. Company Profiles

11.1. Arburg GmbH + Co KG

11.1.1. Company Overview

11.1.2. Product Offerings

11.1.3. Financial Performance

11.1.4. Recent Initiatives

11.2. HAITIAN INTERNATIONAL

11.2.1. Company Overview

11.2.2. Product Offerings

11.2.3. Financial Performance

11.2.4. Recent Initiatives

11.3. KraussMaffei

11.3.1. Company Overview

11.3.2. Product Offerings

11.3.3. Financial Performance

11.3.4. Recent Initiatives

11.4. Milacron

11.4.1. Company Overview

11.4.2. Product Offerings

11.4.3. Financial Performance

11.4.4. LTE Scientific

11.5. NISSEI PLASTIC INDUSTRIAL CO, LTD.

11.5.1. Company Overview

11.5.2. Product Offerings

11.5.3. Financial Performance

11.5.4. Recent Initiatives

11.6. ENGEL AUSTRIA GmbH

11.6.1. Company Overview

11.6.2. Product Offerings

11.6.3. Financial Performance

11.6.4. Recent Initiatives

11.7. Hsong Holdings Limited

11.7.1. Company Overview

11.7.2. Product Offerings

11.7.3. Financial Performance

11.7.4. Recent Initiatives

11.8. UBE Machinery Inc.

11.8.1. Company Overview

11.8.2. Product Offerings

11.8.3. Financial Performance

11.8.4. Recent Initiatives

11.9. Husky Technologies

11.9.1. Company Overview

11.9.2. Product Offerings

11.9.3. Financial Performance

11.9.4. Recent Initiatives

11.10. WITTMANN Technology GmbH

11.10.1. Company Overview

11.10.2. Product Offerings

11.10.3. Financial Performance

11.10.4. Recent Initiatives

Chapter 12. Research Methodology

12.1. Primary Research

12.2. Secondary Research

12.3. Assumptions

Chapter 13. Appendix

13.1. About Us

13.2. Glossary of Terms

Cross-segment Market Size and Analysis for

Mentioned Segments

Cross-segment Market Size and Analysis for

Mentioned Segments

Additional Company Profiles (Upto 5 With No Cost)

Additional Company Profiles (Upto 5 With No Cost)

Additional Countries (Apart From Mentioned Countries)

Additional Countries (Apart From Mentioned Countries)

Country/Region-specific Report

Country/Region-specific Report

Go To Market Strategy

Go To Market Strategy

Region Specific Market Dynamics

Region Specific Market Dynamics Region Level Market Share

Region Level Market Share Import Export Analysis

Import Export Analysis Production Analysis

Production Analysis Others

Others